Client’s profile:

Leading & renowned manufacturers & suppliers of edible & commercial oils and oil-related products. This company produces a variety of edible oils, including cottonseed oil, sunflower oil, corn oil, soybean oil, and groundnut oil. Castor oil, deoiled castor cake, and other commercial products are also produced.

About the Product:

To de-dust and classify the Deoiled Castor Cake, the client required a robust classification and de-dusting machine.

As a result of the extraction of castor oil, a byproduct is obtained called de-oiled castor cake. The residual residues that are left after extracting castor beans are highly valuable due to the high commercial demand they enjoy.

De-oiled castor cake, also known as castor meal, is widely used as a fertilizer and manure because of its rich contents. In addition to nitrogen, phosphorus, and potassium, it contains three essential elements. For crops to grow properly, these elements are essential. Manure of this type does not decompose, making it one of the most natural and organic manures.

Challenges:

Castor meal contains approximately nine to twelve percent moisture, which causes it to form soft lumps and agglomerates. It affects the production process by blocking the mesh and increasing waste as a result of lumps in the mesh.

Additionally, when placed in a giant vibrating sorter, the dry castor meal would cause a great deal of dusting. The requirement for regular maintenance and cleaning would be necessary if there was heavy dusting.

Using an automatic dust-cleaning system in conjunction with a vibrating sieve would solve the problem of lumps and dust.

As a result of aggregation formation, the product is wasted and the mesh gets choked.

In cases where dusting is heavy, frequent maintenance and cleaning are required.

Automated sieving machines can be operated continuously without interruption, thereby reducing batch processing time.

Are you interested in customized solution?

Contact Us Now: De-dust De oiled Caster CakeSolutions :

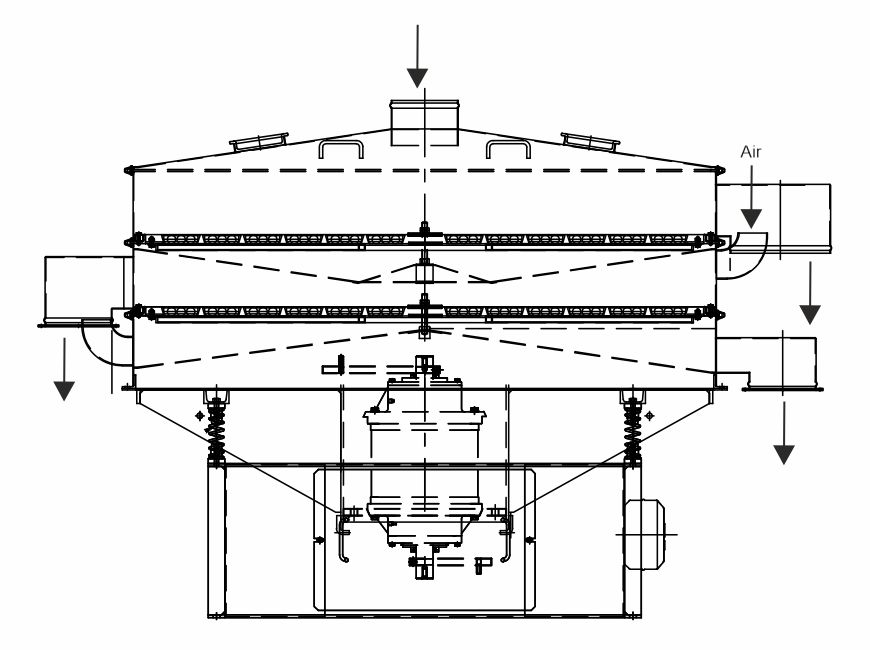

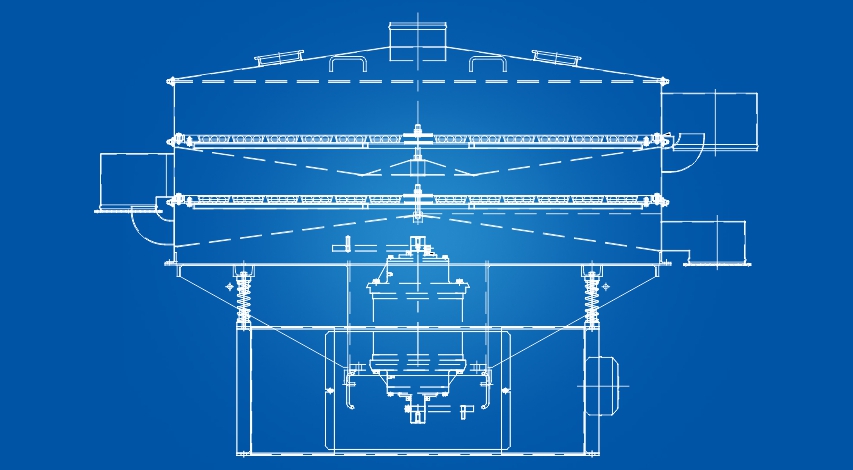

A pair of giant and unique double-decked vibrating gyro separators was designed by Galaxy Sivtek’s designers to eliminate dust by means of air pressure. To removing dust, these separators are equipped with pneumatic mesh cleaning arrangements beneath the mesh. To facilitate the evacuation of dust, each deck was equipped with elbow pipes.

To eliminate the need for frequent cleaning due to heavy dusting, pneumatic mesh cleaning arrangements were implemented. Furthermore, the pneumatic mesh cleaning system facilitates continuous sieving and classification.

To solve the problem of de-lumping and breaking soft lumps, the machines were delivered with mesh de-blinding kits (ball tray arrangement).

There are rubber balls and trays placed between a perforated sheet and mesh to ensure that blind spots are eliminated. During the operation of the machines, balls and trays continuously tap the mesh, which allows soft lumps to be effortlessly broken.

Using two customized Sivtek Super Gyro Separators®, measuring 72 inches in diameter each, the team was able to separate castor meals with maximum ease.

Result

In addition to achieving the desired results, the customized solution also prevented mesh choking, heavy dusting, and product loss.