Client’s profile:

Among Africa’s largest and most renowned sugar suppliers and manufacturers, our client is one of the most prominent. The company produces a range of sugar-related products, including sugar crystals, liquid sugar, brown sugar, and jaggery.

About the Product:

During the processing of sugar cane, the crop is converted into sugar. A variety of by-products are produced in this process, including bagasse, molasses, and filter cake. Upon removing the cane juice from the cane, bagasse is left behind in its dry state.

It is possible to refine sugar to further purify it. A centrifuge is used to separate sugar from heavy syrup after it has been mixed with sugar. The outer coating of the sugar crystals is therefore washed away, resulting in a less pure interior than the outer coating. Following the dissolution of all the sugar, a syrup containing 60% solids is formed.

When phosphoric acid and calcium hydroxide are added to a sugar solution, calcium phosphate is precipitated. Calcium phosphate particles not only entrap impurities but also absorb others, which are then skimmed off the top of the tank. As with the phosphatisation method, carbon dioxide and calcium hydroxide are used in the carbonation method to precipitate calcium carbonate.

Once the syrup has been decolored, activated carbon is used to filter and crystallize it to produce white refined sugar. A certain amount of impurities remain that are adsorbent to carbon in order to remove those that produce color. The syrup is purified before it is concentrated until it reaches supersaturation and crystallized in a vacuum.

Challenges:

To screen 125m3/hr, the customer required a very large screening machine capable of carrying out this task. However, manufacturing such a large machine is not feasible and the required efficiency cannot be achieved.

Additionally, the manufacturer was required to clean the mesh after screening each batch of syrup. As a result, he was required to hire many employees, a process that consumed a substantial amount of time.

The producer faced three challenges, including the distribution system from the overhead buffer tank to the vibrating screen, in which the fluid flow had to be regulated and distributed equally.

Are you interested in customized solution?

Contact Us Now: Sugarcane Juice Filtration In Bulk QuantitySolutions :

Experts from Sivtek were contacted by the giant agglomerate to discuss their concerns. Based on the discussions and understanding of the customer’s challenges, the sales team and the design team devised multiple solutions to address the issues that arose during the various stages of syrup production.

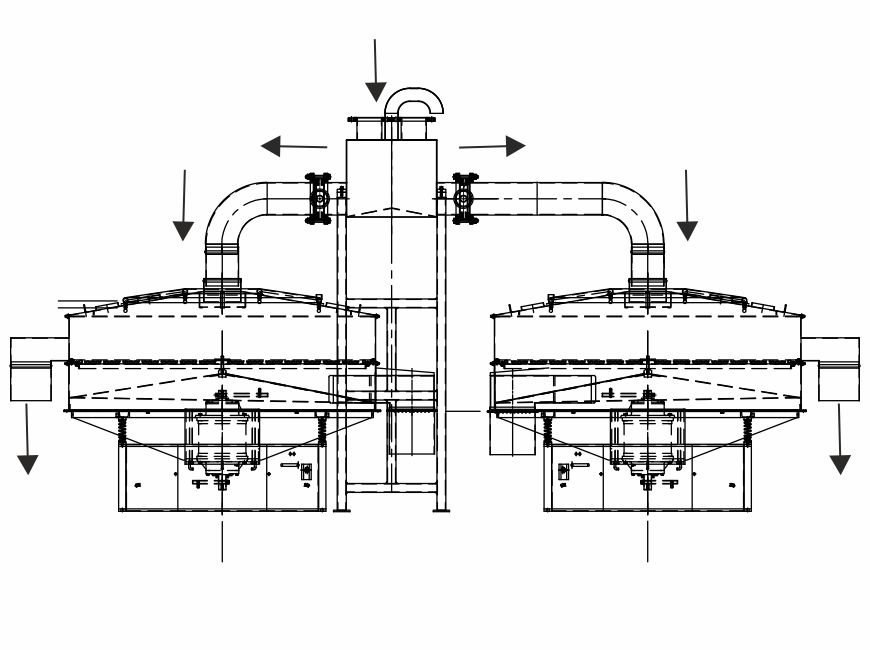

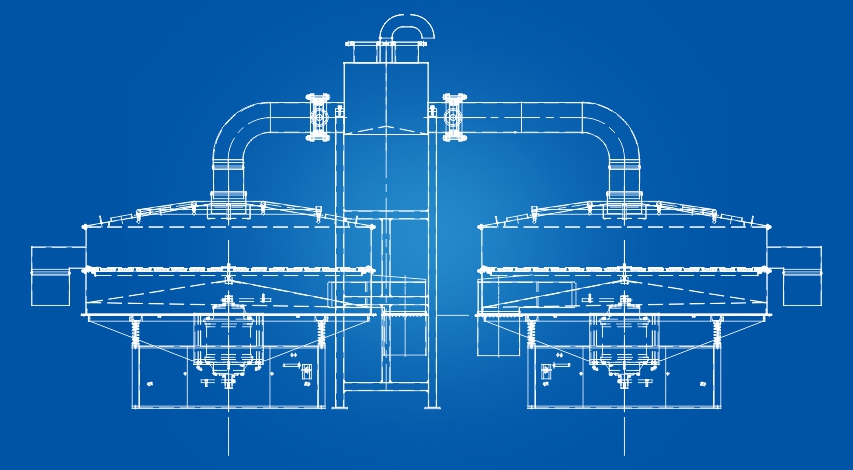

A single deck and mesh deblinding arrangement were provided on three giant Vibro screens, each 84 inches in diameter, enabling the mesh to be unclogged during processing.

As a solution to the second challenge, all 3 machines were installed with a CIP (Clean in Place) system that sprays a pressurized spray of cleaning fluid onto the mesh. Furthermore, a separate arrangement for regulating fluid flow was provided.

Additionally, we constructed a stainless steel distribution system and provided a diverter valve that could be manipulated according to the flow and requirements of the material. The diverter valves on each vibrating screen were opened 33.33% in order to distribute the sugar syrup evenly, allowing a flow rate of 42 m3/hr through each screen.

Result

In addition to achieving the desired output, the customized solution provided helped them to overcome the main problems of handling such a large amount and dividing equally. This was achieved without choking the mesh.