Committed To Quality, Committed To You

We have provided screening and filtering machines to hundreds of companies over the years. Centrifugal sifters, however, stand out for their excellent performance. With its innovative design, this screening machine is capable of screening the finest materials and de-lumps and de-agglomerates the screening material with ease.

Although this is a great machine, there are still some challenges to overcome. In the case of abrasive, sticky, or fine particles, they tend to clog up the screens and rotary blades, reducing efficiency and making screening more difficult.

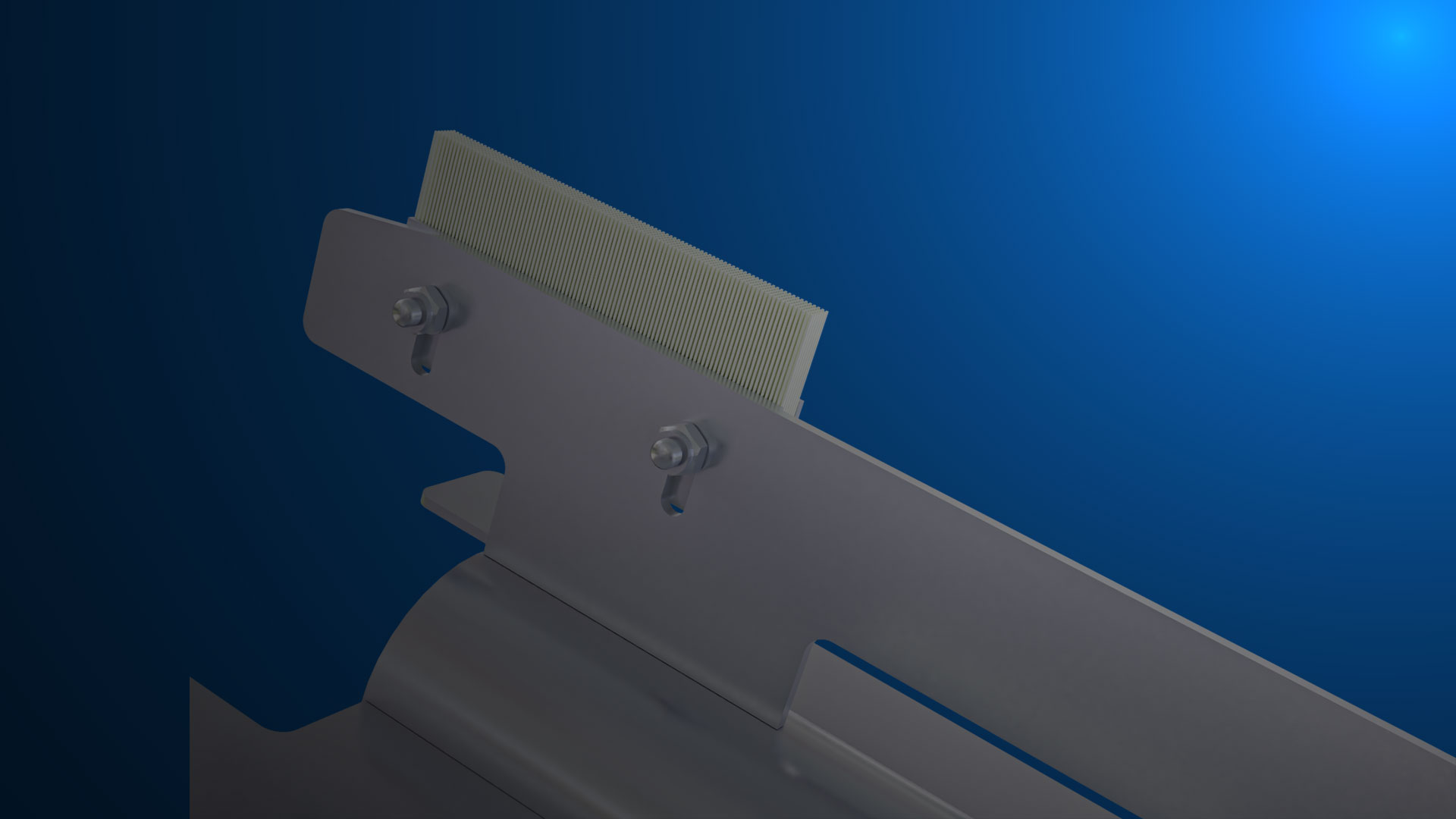

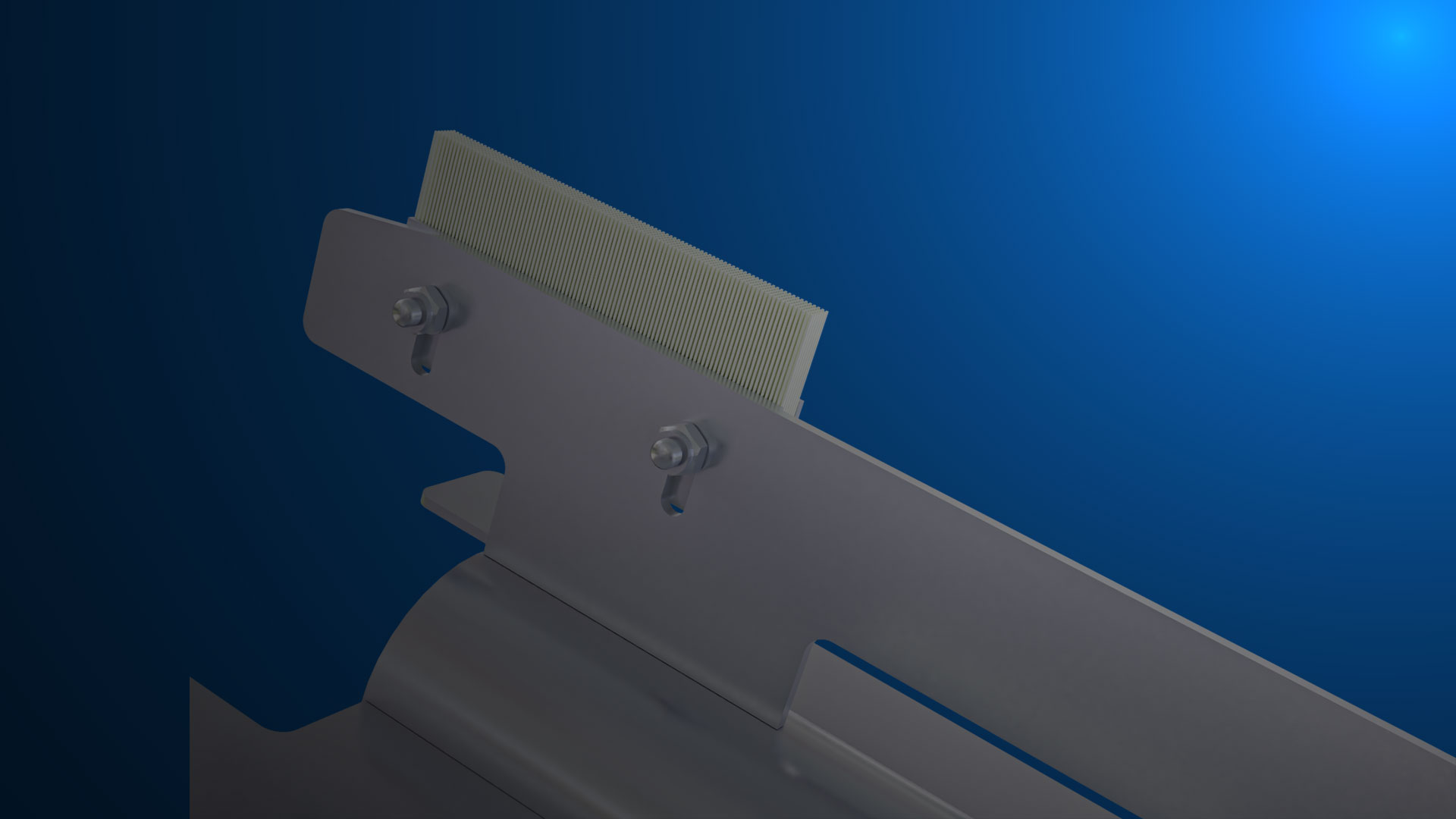

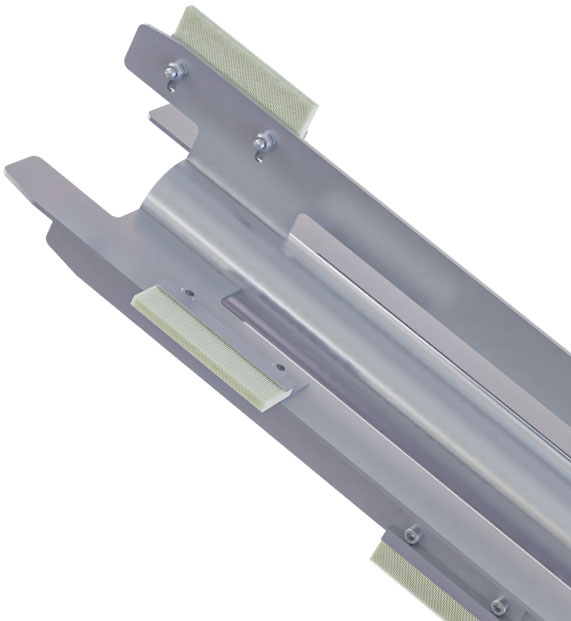

Such situations can be dealt with by deblinding with the brush add-on. The centrifugal sifter is an excellent device for maintaining clean screens and removing any materials that may become stuck within. Furthermore, they can help break down lumps that can accumulate in the screening materials.

With this brush blade add-on, the quality and integrity of the screening material are preserved, which results in a more refined and purified product. Additionally, you will not have to continually declog your sifters, which speeds up the screening process.

Utilizing our brush blade deblinders, we have been able to increase the throughput and quality of our customers’ materials. In addition, it has reduced their production costs since they do not have to spend a great deal of time cleaning and maintaining the screening machine.

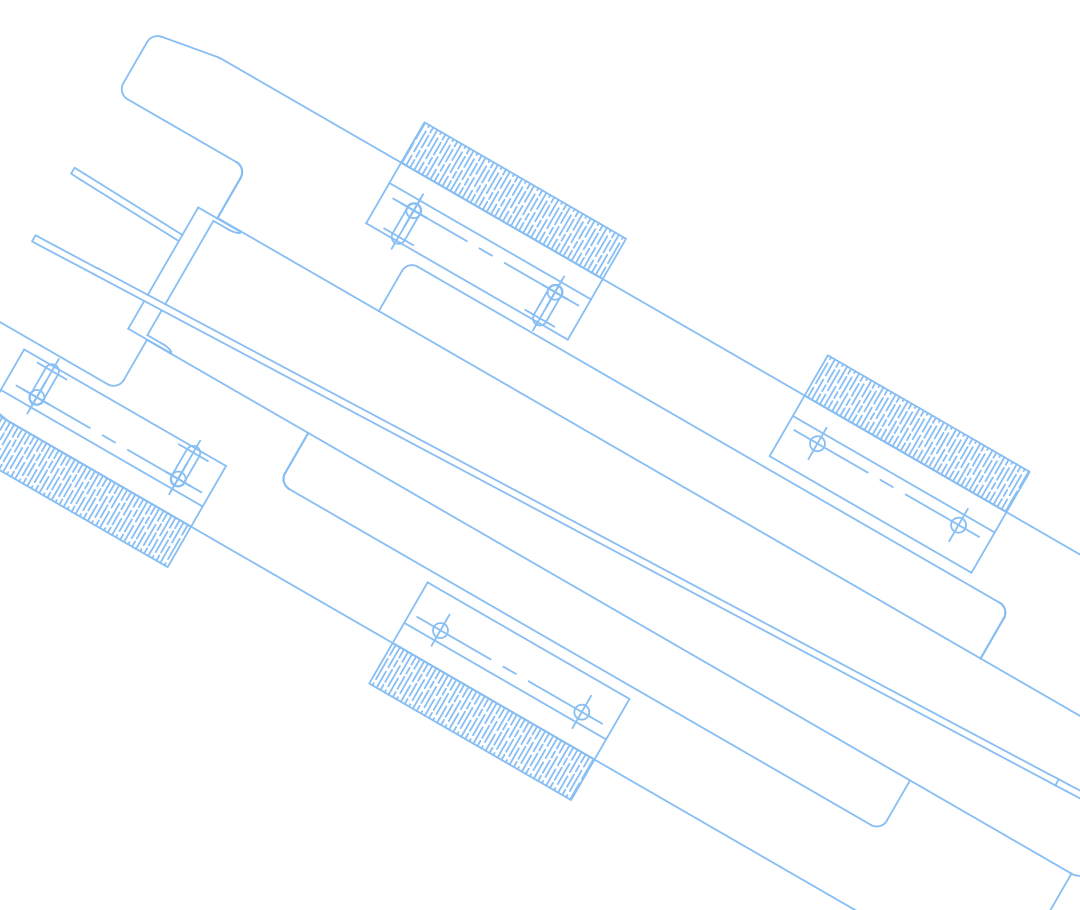

On our centrifugal screeners, we have designed the sifters so that brush blades can be added or removed easily. There is no need to modify the machine's mechanism or to replace any major components. You can use them only to adapt your screening process to the screening material and to achieve the best screening results.

In order to guarantee the safety and sanitation of your screening material, we use FDA and CGMP-approved rubber blades.

With the de-blinding rubber blades, fibrous materials can be scraped from a centrifugal sifter and lumps resulting from screening can be broken.

As a result of their versatility, de-blinding brush blades are used in a variety of industries, including food processing, metal working, and chemicals.

Moreover, brush blades can dramatically increase your throughput without compromising the quality of your screening material.