Committed To Quality, Committed To You

Galaxy Sivtek’s Sandwich screens consist of a mesh top and a support bottom, with balls and sliders in between. As a result of the vibration, the balls and sliders bounce off the support screen and keep tapping the working screen. Whenever small particles or fibers clog the screen, it blinds the maximum screen and minimizes the screening area. By tapping the screen continuously, the ball and sliders deblind the screen.

Sivtek offers stainless steel sandwich screens in all grades. Sandwich screens range in diameter from 18″ to 72″. Get in touch with our Sivtek expert today to learn more.

For the food and pharmaceutical industries, we have a Sivtek compliant ring. There are several problems with silicone bonded screen rings, like the fact that they can’t be reused when they’re damaged or torn, so you have to throw them away and get a new one when they’re damaged or torn. Occasionally the mesh tension will vary, so we need to use our hands or anything that may cause contamination to screen properly.

The loose mesh opening size will result in a poor-quality product. Therefore, we recommend using our FDA-approved ring, which is reusable, and the mesh tension will be the same, so you’ll get the best screening area. Get in touch with our Sivtek expert for more info.

We introduce the new Sivtek Sz screen ring®, which offers unique benefits and features. The Sivtek Sz screen rings® are lightweight and easy to handle.

In Sivtek Sz screen rings®, the mesh is finely and uniformly tensioned to deliver maximum throughput, minimum or no cleaning, and long mesh life. Remeshing screen mesh is also pretty easy & requires only a few tools.

It is lightweight, affordable, precise tensioning, FDA-compliant, and can withstand severe environments.

For more details, contact our Sivtek expert now. The Sivtek Sz screen ring® can be retrofitted into most circular & round sifters.

The Galaxy Sivtek company manufactures complete lead cover assemblies. We can customize the lid to meet your needs. The lid has an inspection window so you can check while it sieves or filters. It prevents dusting and contamination in dusty environments. You can easily fix or remove it with the toggle clamps. To know more about it, please contact our Sivtek expert now.

Transfer chutes or feed trays play a crucial role in separating decks. Basically, it centralizes the material and passes it to another deck for sieving. You’ll get the best gradation this way. With quality, you’ll get more throughput. Use this in all multi-deck gradation systems for optimum results. To know more about it, please contact our Sivtek expert now.

An important part of the sifter is the deck; it is designed according to the user’s needs. The inner surface (mirror finish) is smooth to prevent contamination, and the outer surface is smooth for some applications. Additionally, the product is available in various heights, multiple spout options, and a variety of diameters. To sieve the material, we use this deck to support our mesh, and the material passes through its perimeter before exiting the spout. To know more please contact our expert now.

Galaxy Sivtek provides an easy-to-use solution that maintains the quality of the product. Toggle clamps are one of the components that can be used to easily assemble and disassemble the separator deck. In addition to being durable, our clamps are also compliant. With our toggle clamps, you can operate safely. To know more please contact our expert.

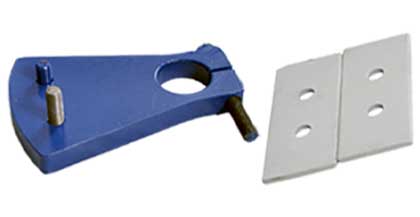

It is necessary to use auxiliary plates in any vibro sifter in order to achieve optimum throughput and quality. In terms of vibration, we have already added standard eccentric weights for the required amount of vibration (X) in order to sieve your application. However, occasionally more vibration is required to sieve or filter, so we have added auxiliaries plates to add an additional amount of vibration (X+). By using these plates, we can get the right vertical vibration for any application and get the best results. To know more please contact our Sivtek expert now.

A vibro sifter machine needs a base that keeps it in place, while a column supports and connects the upper mechanical components. Additionally, fine-tuning and agitator options are available. To know more please contact our Sivtek expert now.

Silicon Nitrite

Rubber Gasket

Galaxy Sivtek offers gaskets in a variety of sizes and diameters. To prevent leaks from sifters and separators, gaskets are required. Galaxy Sivtek manufactures gaskets made of silicone, neoprene, and nitrile. A wide range of rubber gaskets are available for Vibro sifters, screeners, and separators. Galaxy Sivtek can provide you with FDA-approved gasket materials depending on your requirements. For more detail please contact our expert now.

Galaxy Sivtek manufactures and supplies all major parts for vibratory screens and sifters. These include anti-vibration mounts, which provide isolation from adjoining structures and allow the vibratory force necessary to separate the products to be applied. Vibration isolation is designed to reduce the transmission of vibration, so it will support the surrounding structure and can reduce vibration by up to 95%. To know more please contact our expert now.

Galaxy Sivtek understands that everyone processes different types of applications. It is possible to use a variety of balls and sliders depending on the application to achieve the appropriate throughput without compromising the quality of the product. It is possible to remove the chocked particles from the working mesh by placing this Deblinding kit on a perforated plate or coarser mesh.

For food processing or similar kind of application, we suggest Silicone rubber ball, for mineral or metal materials, we recommend Neoprene, and for flameproof materials, we recommend Nitrile rubber ball. Similarly to rubber balls, we have nylon and PVC sliders. Contact our expert to know more about our sliders and rubber balls.

Vibro sifters sieve or filter your product at the outlet through a rubber bellow, which can be connected to anything else. It is through this bellow that the material passes. Rubber bellows can be used for a variety of applications, including dry, wet, sticky, oily, food-grade, abrasive, low temperature, and high temperature.

Please contact our Sivtek expert to know more about our rubber bellow.

In general, springs and retainers are interconnected. It is the retainer that holds the spring and provides it with support, while the spring is responsible for absorbing vibrations. With this set, you will be able to keep your sifter running smoothly. To know more contact our expert now.

Galaxy Sivtek’s rubber sleeves feature a smooth inner surface and a seamless rubber tube. As the name implies, these sleeves are manufactured on a mandrel without bonded seams. The outer covers can be ground smooth if necessary. Get in touch with our experts to learn more about our rubber sleeves.

In order to separate materials, they hold the upper section of the unit in place while it vibrates. They serve as a damper in a broader sense. Therefore, the machine can vibrate freely.

It is necessary to use springs in order for the machine to move hydraulically. The springs hold the upper component in place while the machine vibrates and processes the materials.

The Galaxy Sivtek Vibro Sifter comes with a castor wheel mount. There is a wide range of applications for our castor wheel vibratory sifters. A portable vibro sifter mounted on a castor wheel allows you to separate and grade materials by gyratory vibration. Castor wheels made of stainless steel can withstand wet conditions, corrosive environments, and sanitary conditions. Contact our expert to know more about castor wheel.

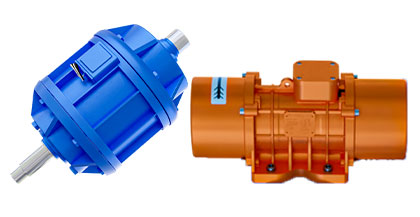

There is no doubt that the motor is the most important component of a vibro sifter or centrifugal sifter. Our goal at Galaxy Sivtek is to provide quality in every aspect, regardless of whether it is a vibratory motor or a standard electric motor. Therefore, we use high-quality motors in our sifters, which must operate continuously without interruption.

We always provide you with the best vibration motors for vibratory separators and sifters. No matter if the motor is mounted on a foot or flange, we offer the best vibratory motors. You can achieve the perfect vibrations by fitting eccentric weights at the top and bottom of the shaft. Vibratory motors are available for all types of sifters and separators. To know more please contact our Sivtek expert now.