Committed To Quality, Committed To You

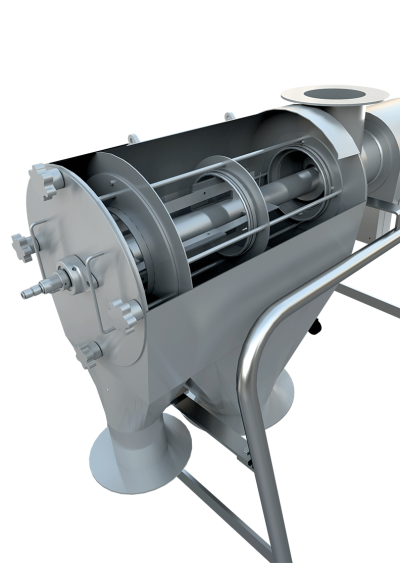

The Pneumatic Roto Screener efficiently separates particles using a combination of centrifugal force and air flow. Material enters the chamber and is subjected to a spinning mesh screen. Fine particles pass through the mesh, while larger particles are directed out of the chamber. This process ensures precise separation and a dust-free operation. Its compact design allows for easy integration into existing systems, enhancing both product quality and processing efficiency.

In order to monitor the screening process, Sivtek's Pneumatic Roto Sifter® features convenient inspection windows.

It is firmly designed to contain the screening material in the Sivtek Pneumatic Roto Sifter®. It increases safety while operating with hazardous substances.

Vibrations are minimal and the noise level is below 80DB.

With its closed system operation, it can maintain the highest hygienic standards in the pharmaceutical and food industries.

With its compact design, the Sivtek Pneumatic Roto Sifter® is more flexible and manoeuvrable.

It is very easy to clean the machine since it has multiple options and knobs to disassemble it.