Committed To Quality, Committed To You

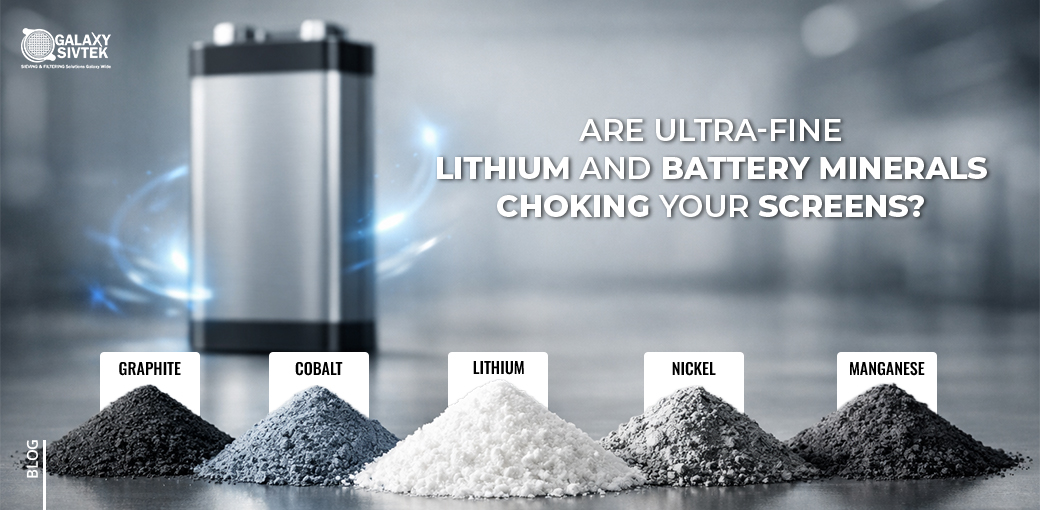

Battery minerals such as lithium, manganese, nickel, cobalt, and vanadium are the foundation of modern energy-storage systems—electric vehicle batteries, grid-scale storage units, and renewable energy technologies. While mining and chemical processing receive most of the attention, one step quietly determines the performance and efficiency of the entire value chain:

Screening and particle-size classification.

Battery minerals behave differently from traditional ores. They may be abrasive, ultra-fine, moisture-sensitive, or prone to agglomeration. If particle size is not controlled before chemical conversion, the material loses reactivity, recovery drops, and downstream equipment suffers. Screening is therefore not just a preparatory step—it is a quality-control gateway that stabilizes the beneficiation process.

This article discusses why screening is an important process, the issues associated with each mineral, and how Galaxy Sivtek provides engineering solutions for battery mineral processing.

Each battery mineral has specific physical properties:

Lithium (Spodumene / Lithium-bearing minerals)

Soft, yet during grinding very fine particles may be formed. It is critical to classify accurately in order to avoid losing any fine-grade lithium content.

Manganese (for MnSO₄ production)

Often sticky, moisture-retaining, and variable in particle size. Needs controlled separation to avoid overgrinding and maintain consistent feed chemistry.

Nickel Laterites

Clay-rich, sticky, and highly abrasive. Screening defines consistency of slurry and enhances the efficiency of leaching.

Cobalt Ores

Occur with iron and copper impurities. Screening helps separate unwanted fines and stabilize the concentration stage.

Vanadium-bearing ores

Require controlled sizing before roasting or leaching. Oversize particles reduce extraction rates.

Across all these minerals, incorrect particle size distribution (PSD) leads to:

This is why screening is fundamental in every beneficiation flow.

Battery minerals are not easy to classify. The process engineers mainly encounter the following problems:

1. Mesh Blinding & Agglomeration

Lithium fines and manganese particles stick to the mesh, blocking the screen.

2. Abrasive Wear

Nickel and cobalt ores wear down normal screens rapidly.

3. Ultra-Fine Particles

Battery minerals may need to be classified to less than 100-75 microns.

4. Variable Moisture

Wet feeding results in bad separation, and the throughput becomes inconsistent.

5. Strict PSD Requirements

Chemical-grade material requires narrow size distribution.

Major problems arise due to offline cleaning, repeated shutdowns, and fluctuating feed quality blocking the process flow.

Galaxy Sivtek offers screening systems that are designed to handle abrasive, fine and moisture sensitive battery minerals, which would have a consistent operation through the beneficiation steps.

Removes:

This helps to protect crushers and also stabilizes the feed.

Recommended Equipment:

SIVTEK RotoSifter – Perfect for high-volume, coarse removal.

Purpose:

Recommended Equipment:

SIVTEK Vibro Separator (multi-deck) – Classifies ore into correct size fractions.

Critical in lithium, manganese, vanadium, nickel and cobalt and particle size <100 µm is needed.

Challenges:

Powder blinding, ultra-fines bypassing, and ineffective separation.

Recommended Equipment:

Ultrasonic SIVTEK Separator

This is done when the minerals are in the form of slurry during processing.

Some examples of application are:

Recommended Equipment:

SIVTEK Dewatering Screens – Fast moisture loss, reliable handling.

Battery minerals differ from other metallic minerals in several respects. Some of the common problems include:

1. Fine Powder Blinding

The powders of lithium and manganese have a great tendency to clog the conventional screens.

2. Abrasive Wear

Nickel and cobalt ores wear out screens quickly without reinforced designs.

3. Moisture-Induced Agglomeration

When the materials are wet or moist, lumps are formed that either pass incorrectly or stick to the screen.

4. Narrow PSD Requirements

Battery-grade feed must be particle-size specified very strictly.

5. High Throughput Expectations

Processing facilities cannot afford to have bottlenecked operations at the screening process.

These challenges demand equipment engineered specifically for mineral and powder behaviour—not repurposed general-purpose separators.

Galaxy Sivtek’s systems are designed for industrial minerals with demanding performance requirements.

Anti-Blinding Ultrasonic System

Prevents blockage when screening ultra-fine lithium, manganese, or vanadium powders.

Heavy-Duty Construction

Withstands abrasive ores such as nickel and cobalt, improving lifespan and reducing downtime.

Multi-Deck Vibro Separators

Enable accurate classification at several size levels simultaneously.

High-Capacity RotoSifter

Ensures ROM material enters the circuit free from debris and oversize lumps.

Efficient Dewatering Screens

Processing slurries, reduce moisture, enhance drying processes, enhance chemical processes.

Custom Mesh & Flow Configurations

Each mineral is unique in its characteristics. The mesh size, vibration pattern, deck arrangement, and feed distribution are all created according to the specific mineral’s flow properties.

Together, these systems provide:

Battery-mineral processing demands screening systems that can:

Galaxy Sivtek offers equipment purpose-built around these needs, with proven performance in minerals, metals, chemicals, and fine-powder applications. The focus is simple: accurate separation, maximum uptime, and predictable processing behaviour.

For lithium, manganese, and other battery minerals, screening determines the efficiency of every subsequent processing stage. It stabilizes feed, controls particle size, and ensures the mineral behaves predictably during grinding, leaching, flotation, or chemical conversion.

Galaxy Sivtek’s screening systems address the exact challenges battery-mineral processors face—fine powder blinding, moisture, abrasive wear, and narrow PSD requirements—delivering reliable, high-precision separation at every stage of the flow.

Accurate screening is not an add-on to battery-mineral processing; it is the step that keeps the entire beneficiation line efficient, consistent, and scalable.