Committed To Quality, Committed To You

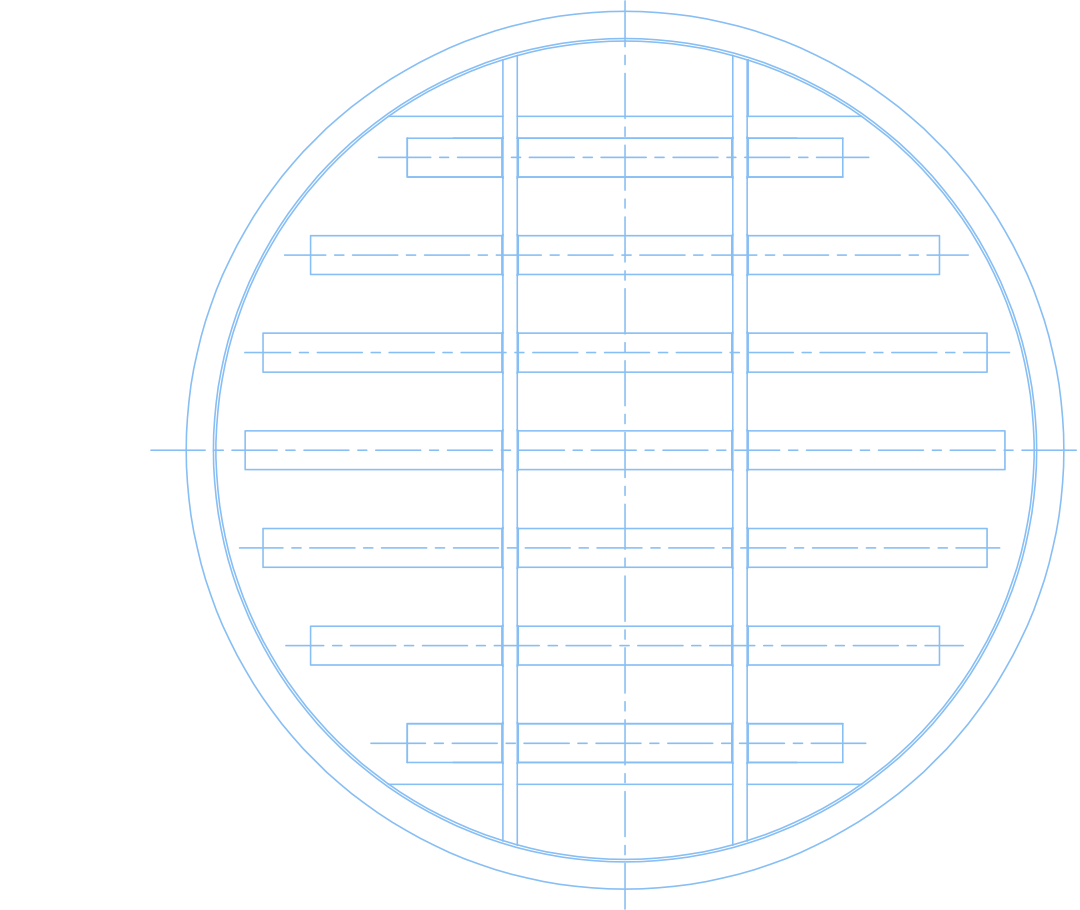

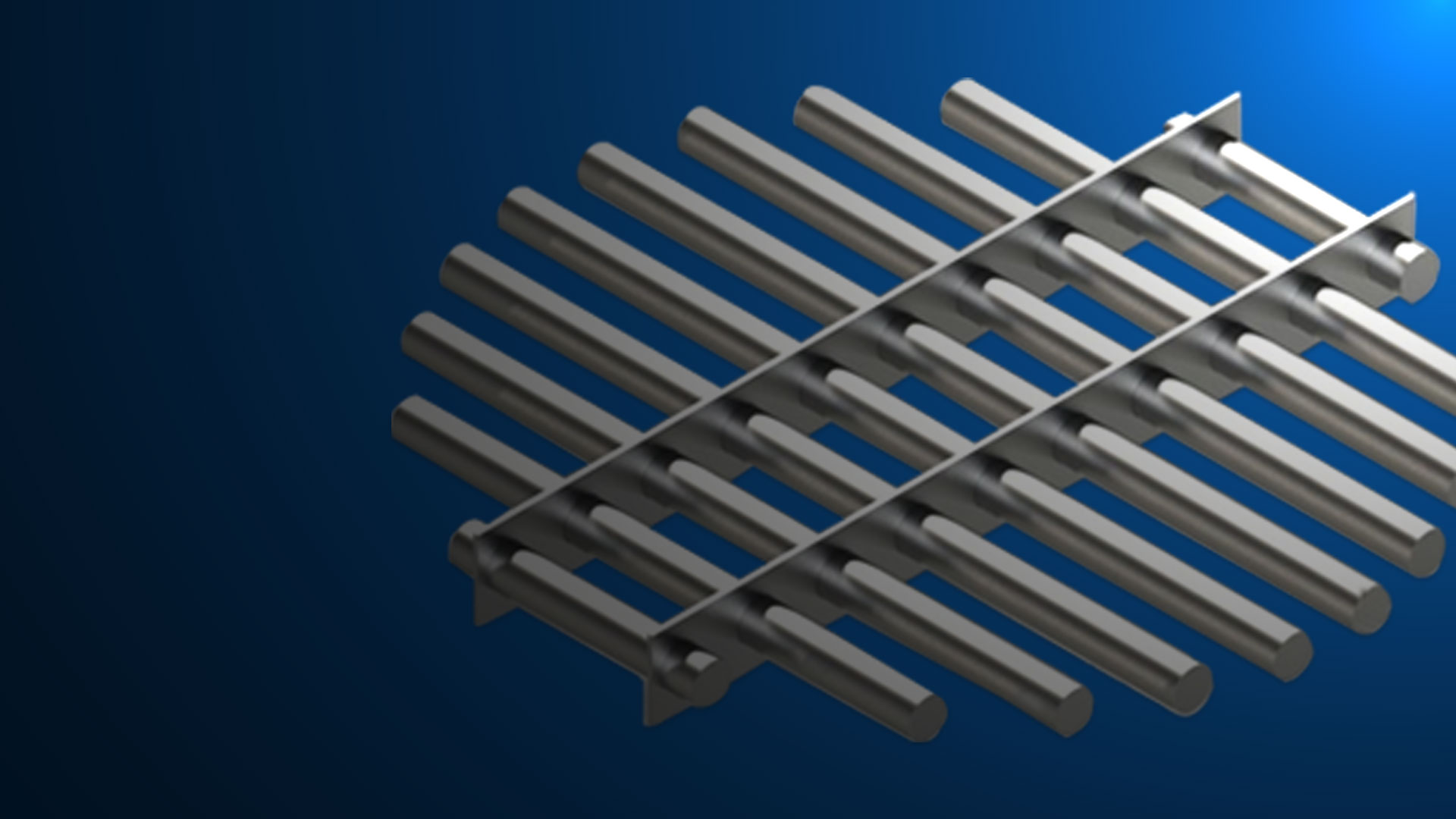

Galaxy Sivtek offers stainless-steel magnets that provide high intensity, high gradient fields for removing ferrous contaminants from the processing material in order to maintain hygiene standards. These magnets are also available in various shapes and sizes, depending on the requirements.

The use of magnetic grills or magnets during the processing of any material is possible at various stages of the process in order to retain ferrous contaminants attached to them while the remaining required material falls off and is moved forward through these magnets when the material passes through them.

Material is checked and screened to ensure quality is not compromised.

This magnet helps reduce delays and missed commitments caused by heavy ferrous particles such as screw nuts and bolts.

The magnetic intensity can be increased up to 12000 gauss.

Magnets of this type can operate at 350°C.