Committed To Quality, Committed To You

The Ultrasonic Sivtek is an innovative sieving machine that uses ultrasonic frequencies to screen difficult materials. The process of processing raw materials is being transformed by it. By easily breaking down hard and difficult dry materials, you can screen a wider variety of materials.

Sivtek’s Ultrasonic Frequency Machines are powered by a transducer that breaks chemical bonds between molecules and crumbles materials.

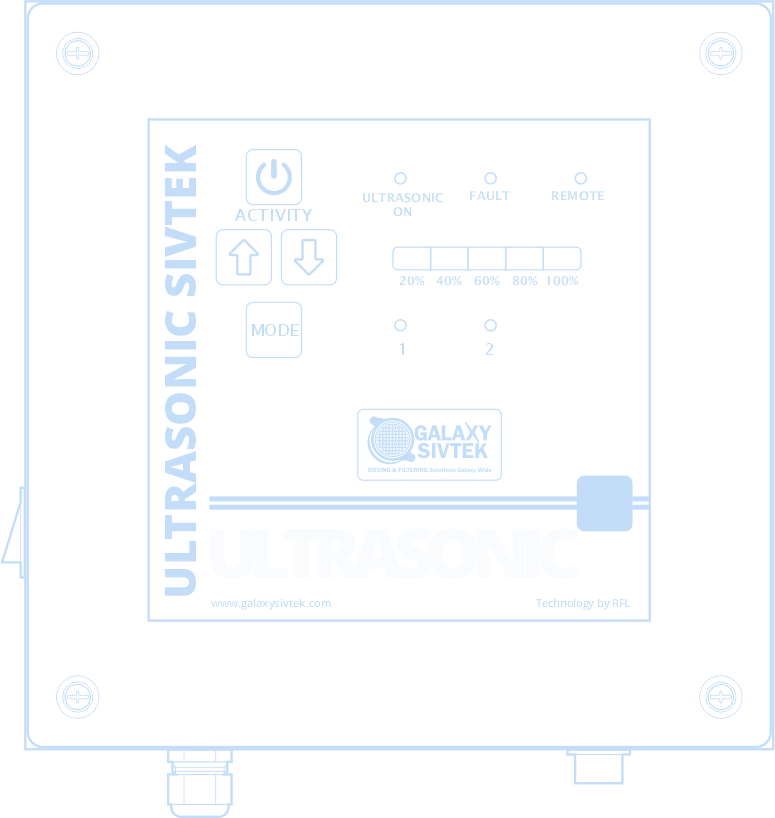

With its 100W power system, the Ultrasonic Sivtek can measure fault frequency and temperature. Enhancing your control over the screening process allows you to calibrate the results according to your needs. It can also allow accurate separation down to 20µ.

In addition to breaking down the materials, the screens and the machine are not moved by ultrasonic frequencies. Moreover, the machine’s robust design allows it to continue working without taking a break for extended periods of time.

This robust and innovative method of screening dry products has increased production rates in numerous industries. Moreover, as the machine involves minimal screen movement, the screen life has been extended as well.

Using an acoustically coupled component, the Ultrasonic Sivtek transmits ultrasonic frequencies through a piezo transducer. Signals are received by transducers in the form of amplitude, frequency, and phase controlled signals.

Further, the machine's robust design allows it to operate continuously for extended periods of time.

This machine uses ultrasonic frequencies to alter the surface tension of materials in order to effortlessly break molecule bonds.

You can also remove fine particles from agglomerated and dry materials using the Sivtek Ultrasonic. Separation can be accurate down to 20 microns.

The machine can be retrofitted seamlessly into existing vibrating separators in your current processing line.