Galaxy Sivtek was commissioned by an internationally recognized paint and pigment manufacturer to design and provide a customized solution.

Client’s profile:

The company is one of the largest manufacturers in India of paints, pigments, wallpapers, waterproofing solutions, etc. For more than seven decades, the company has provided solutions to numerous paint and chemical requirements. The company manufactures a wide variety of paints, pigments, dry paints, chemicals, and various other items.

About the Product:

They were seeking a robust classification and screening machine capable of sieving and screening liquid paint. This was in order to identify contaminants, minute particles, and other unwanted materials that could adversely affect the product.

Our customer requested that we sieve a water-based acrylic emulsion suitable for moderately humid to dry climates. Among the special features of this product are its weather resistance, its long shelf life, its non-toxicity, its absence of APEO (Alkylphenol Ethoxylates), and its environmental friendliness.

It is pertinent to note that both paints are manufactured by complex processes and using complex materials. During the manufacturing of paint, pigments such as titanium dioxide, chrome colors, and zinc oxide are mixed with solvents such as hydrocarbons and alcohol.

In the course of manufacturing and mixing, the different chemical properties of the ingredients can lead to the formation of lumps. In addition, the paint was contaminated during the manufacturing process. Therefore, it was necessary to filter it in order to remove lumps and ensure that it was free of contamination.

To separate oversize and foreign particles from the final filling, nylon bag filters were used. They encountered the following difficulties when using nylon bag filters:

It is necessary to replace the bag frequently since the paint is viscous and does not pass through the bag easily during the filtration process. Squeezing the bag to ensure that the paint passes through expands the opening of the mesh. As a result, lumps pass through the mesh openings of the final product, resulting in the need to change the bags more frequently, which increases production costs.

Due to the increased use of nylon bag filters, the company was required to maintain a stock of nylon bag filters. By investing in bags, the company increased both its operating costs and its investment.

Disposal of used bags: Considering the strict environmental policies of the company, storing and disposing of discarded bags has become a challenge. Moreover, they were required to invest in the proper disposal of used bags, which consequently raised their production costs.

Manpower: Due to the manual nature of the filtering and packing processes, more manpower is required for these processes.

Breakthrough in the Manufacturing process: With nylon bag filters requiring frequent replacements, it was not possible to implement a continuous manufacturing process, which again impacted production costs and operational efficiency.

Are you interested in customized solution?

Contact Us Now: Liquid Paint Filtration With Dual FilterSolutions :

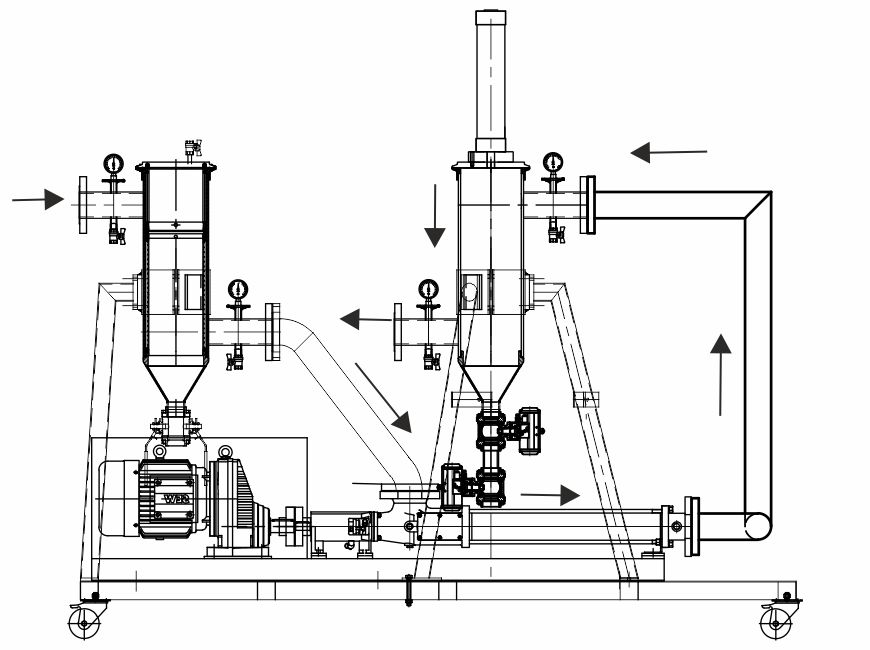

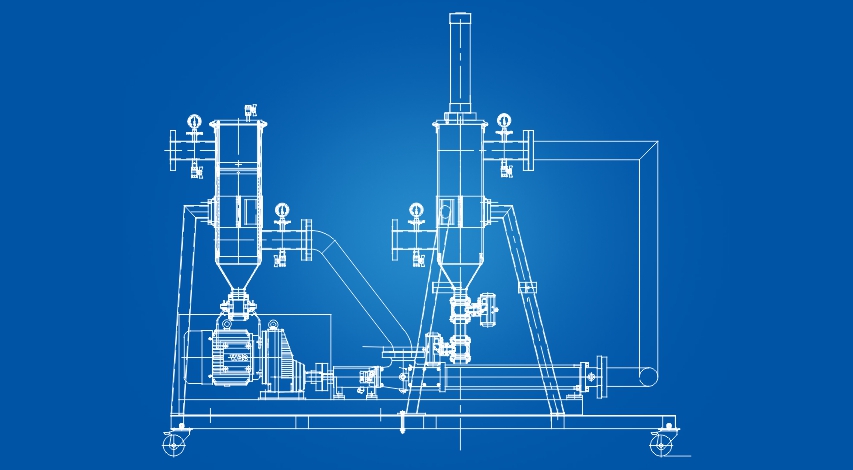

Before the self-cleaning filter is activated, Galaxy Sivtek developed a customized filter arrangement to remove lumps and clumps. Consequently, the material was screened twice before it was processed in accordance with this custom arrangement.

Before entering the progressive cavity pump (screw pump), the raw material was screened in order to reduce lumps. An elastomer stator with two internal helixes and a precision machined rotor with one external helix make up the pump’s pumping element. A special profile of the rotor and stator set ensures that the sealing line formed between the rotor and stator set remains intact during static and dynamic operation.

The raw product should not contain lumps or agglomerates in order to prevent damage to the pump body, i.e. the stator or the rotor. To resolve this issue, a special perforated screen with a 2mm opening was utilized. This removes sharp bumps from the filter and prevent it from becoming clogged.

Upon pre-filtering the water-based paint, the final contaminants were removed by fine screening using a self-cleaning filter equipped with a 600-micron bracket. Fluid is supplied by a progressive cavity pump at a constant pressure.

Result

Through the customized solution, they were able to achieve their desired output as well as resolve the main issues of choking, reduced time, and reduced manpower.