Several factors contributed to a labor, time, and cost issue for one of India’s largest food and beverage processing start-ups. A customized solution was developed by Galaxy Sivtek’s research and development and design teams.

Client’s profile:

In addition to producing, processing, and distributing organic products worldwide, the company also exports them. Besides producing organic products, the company also promotes environmental conservation, sustainable agricultural development, and Indian farming communities.

Challenges:

During the development of their sieving and filtering solution, Galaxy Sivtek was contacted by the engineering team of the company. There were a number of concerns expressed by clients.

The biggest concern was labor costs and labor time associated with manually feeding flour bags into the screening machine, which took an excessive amount of time and was not cost-effective. Furthermore, it constitutes a health hazard for individuals carrying it manually as well.

Our attention was also drawn to a problem with conveying and dumping the material onto the vibratory screen. Moreover, this was a manual process, resulting in irregular flows and altered outputs.

As well as maintaining the quality of the product, ferrous contaminants had to be removed from the product as well. An expert panel conducted a thorough examination before reaching a conclusion.

Due to the extensive requirements of the customer, the design and R&D team visited the manufacturing facility in Madhya Pradesh. The technical director explained the entire system’s process flow and requested a response within a short time period.

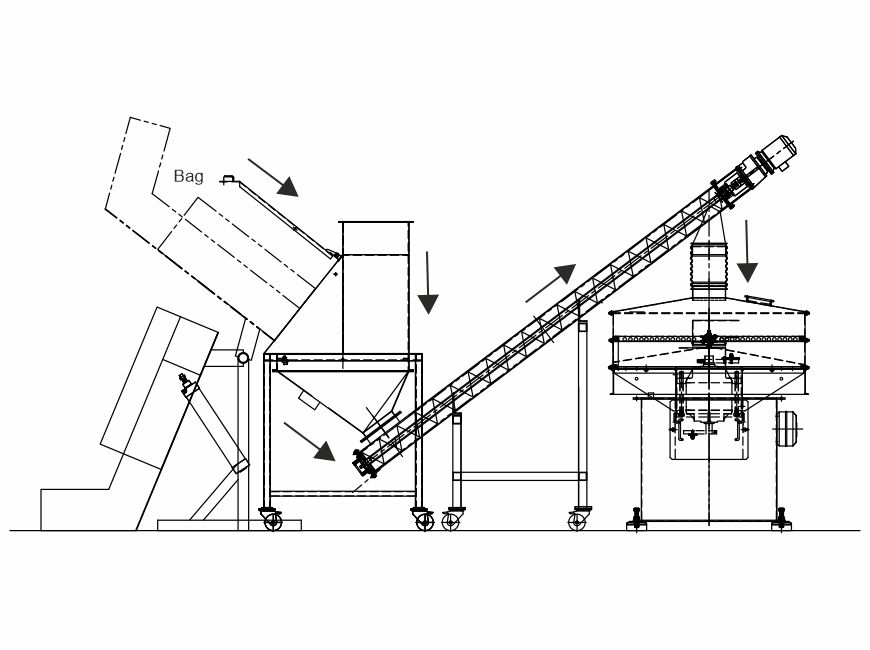

Step by step, the design team faced this problem and developed a pneumatic bag tilter that could lift weights up to 70 kilograms. It could then be dropped off at the bag dump station, where two pneumatic ball vibrators were installed to prevent material accumulation by tapping the hopper mechanism.

We also addressed the problem of material handling and transfer by designing a screw conveyor. This would transfer material from the bag dump station to the Vibro screen for sieving.

The oversize and undersized particles were graded at two levels in this instance. Using the sandwich screen ring, consistent screening is achieved as well as increased mesh strength. Upon the material’s exit, a magnetic grill is provided to ensure that no ferrous contaminants have been introduced.

Are you interested in customized solution?

Contact Us Now: Screening With Material Handling SystemResult

With a customized solution, they were not only able to achieve the desired output, but they also resolved the main problems associated with picking up bags and disposing of them at the dumping station. Using the material conveying system, smooth material flow and product loss were reduced.