Committed To Quality, Committed To You

To sieve any dry material, powder, or liquid, you will need a quality screen or mesh. It is likely that the mesh will be torn or loosen, which will affect the final product. The opening size of the mesh in most local brands will increase after a few days or months of use, resulting in a reduction in quality. We provide wire mesh of the highest quality. Contact us for more information.

When screening materials such as plastic pellets, candies, or almonds, perforated sheets are used to remove impurities. Blank areas at the edges of the sheet facilitate the removal of long-shaped particles. Perforated sheets are superior to wire mesh in such applications because they have a longer life and provide a more accurate screening process. Additionally, it supported the de-blinding kit. As a result of its smooth surface, the ball tray is easy to move and provides strong support to its bottom. To know more about the perforated sheet please contact our Sivtek expert.

Synthetic polymers have numerous properties, including chemical and electrical resistance, flexibility, insulating capacity, flexural strength, and thermal stability. In such applications, polymer mesh is much more effective than other types of mesh. Get in touch with our Sivtek experts to learn more about Polymer Mesh.

The use of perforated mesh sheets, or perforated mesh panels, is widespread in many industries. Metal sheets are punched with thousands of small holes to create mesh with a perforated plate. Perforated mesh. We are recognized as one of the industry’s most trusted names when it comes to distributing high-quality perforated mesh sheets. To know more about the product contact our Sivtek expert.

In centrifugal sifters, rotary baskets are used to sieve material. In order to sieve your products accurately, Galaxy Sivtek provides the appropriate basket with stainless steel mesh. We can provide a basket with an additional support of perforated sheet if the mesh you require is very fine. Thus, the mesh can last longer and quality sieving can last longer. To know more please contact our sieving expert.

Among Galaxy Sivtek’s centrifugal sifters, it stands out for its exceptional features and unmatched benefits. The stand is constructed from high-quality materials in order to ensure that the centrifugal sifter operates efficiently without being obstructed. We provide To know more about the product contact us.

The door is an integral part of the centrifugal sifter. The door allows us to observe the process of processing the product. This product is made of high-quality metal and features silicone gaskets that have been approved by the FDA. These doors are equipped with airtight clamps in order to prevent the loss of products. For more information contact our expert.

Shafts are integral parts of centrifugal sifters. The product is made from high-quality steel that is EN8 certified. Furthermore, the shaft is equipped with a paddle arrangement that produces centrifugal force in order to sieve the material. Strong and balanced shafts support the paddle arrangement. For more information contact our expert.

The machine body is the main component of the machine. There are four types of finishing available for a body: mirror, brush, bead blast, and paint. High-quality materials are used in the construction of the machine body, which is designed to be robust. For more information contact our sivtek expert.

A centrifugal sifter uses a trapezoidal belt to transmit maximum force from the motor to the shaft, as these belts offer a very high strength, which can transfer and withstand higher forces of the processing material. For more information contact our experts.

Silicon Nitrite

Rubber Gasket

Gaskets from Galaxy Sivtek are available in a range of diameters to meet the requirements of all kinds of applications. For all kinds of sifters and separators, gaskets play a vital role in preventing leaks. Among Galaxy Sivtek’s gasket materials are silicone, neoprene, and nitrile. All kinds of rubber gaskets for Vibro sifters, screeners, and separators. As Galaxy Sivtek understands your needs and applications, we can provide you with the correct material for gaskets if you need them for food applications. For more detail please contact our expert now.

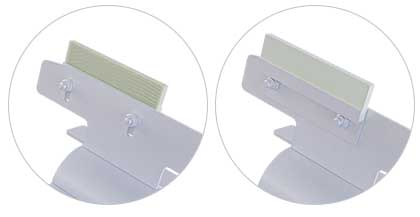

The best option is to use a centrifugal sifter and brush cleaner. When fine mesh material is sieved, a brush rotates the shaft while cleaning the screen along the mesh. It is no longer necessary to manually clean the mesh. no need to remove the shaft and disturb your production line.

you just have to install this in your rotary sifter and let it clean automatically. This has been used by many industry leaders and they are getting very good results. Due to the elimination of chocking, throughput is increased. Due to the lack of manual cleaning, the production line runs smoothly.

Centrifugal sifters use a front bearing to assist the shaft to rotate at the desired speed while reducing friction between the surfaces. Ball bearings are equipped with special seals to prevent contamination and choking. For more information contact our experts.

Centrifugal sifters are controlled by VFDs. VFDs provide smooth control and reduce power consumption. Flow control with variable speed motors is more efficient than other methods. For more information contact our Sivtek Expert.

The motor is the most important part of any vibratory sifter or centrifugal sifter. We at Galaxy Sivtek believe in quality in every aspect, regardless of the motor type. That’s why we are using the best motors for our Vibro sifters which must work 24/7 without any interruption.