Committed To Quality, Committed To You

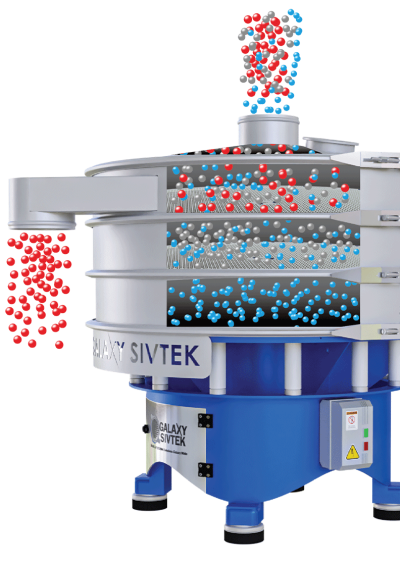

Our Super Gyratory Separator produces such high-intensity vibrations due to its eccentric weights on either side of the motion generator shaft. The top weight distributes the material over the screen, but the bottom weight tilts the material to generate vertical vibrations.

The Super Gyratory Separator can easily be integrated into existing processing lines due to its compact design.

Gyratory separators are equipped with adjustable lead angles, which allow the fineness of the separation to be controlled.

Due to its compact design and castor wheels, the Super Gyratory Separator is highly mobile.

The Gyratory Separator has a sturdy construction that is capable of handling all types of materials at high vibration levels.

Gyratory separators require little to no maintenance, thus reducing operating costs.

Super Gyratory Separators are highly maneuverable thanks to their castor wheels.