Committed To Quality, Committed To You

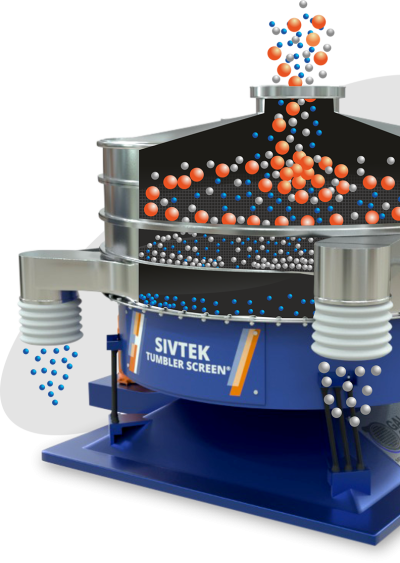

Our Tumbler Sivtek continuously feeds screening material into the middle of the top screen, where it spreads evenly across the entire surface. The material passes through a circular motion, allowing finer particles to pass through the center and coarse particles to exit. By using lateral outlets, each fraction is discharged.

During operation, the SIVTEK Tumbler Screen firmly contains the screening material. Consequently, it increases safety when working with hazardous substances.

The tumbler screening machine can grade particles up to 6 sizes with a 5 deck screen.

SIVTEK's Tumbler Screen maintains a noise level of 75DB, which is lower than any conventional vibro sifter.

The elliptical movement of the machine creates a three-dimensional tumbling motion that increases efficiency by 99%.

Compared with other vibrating separators, SIVTEK Tumbler Screens operate at 3-4 times lower acceleration.

Due to Tumbler Screen's streamlined screening process, less manpower is required.